|

|

|

|

|

September 2004

|

|

|

PROJECT MAY

Sponsored by

®

|

|

|

|

September 4

-

Mr. Widget

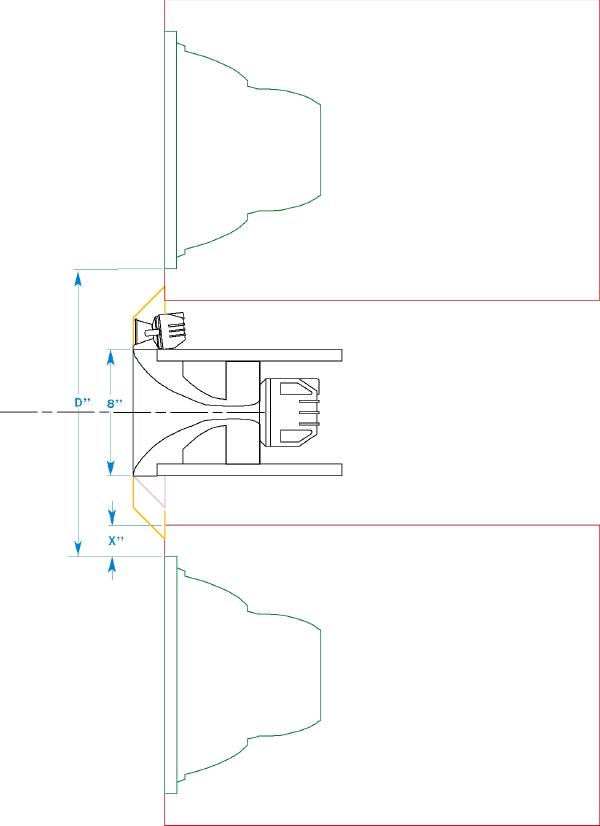

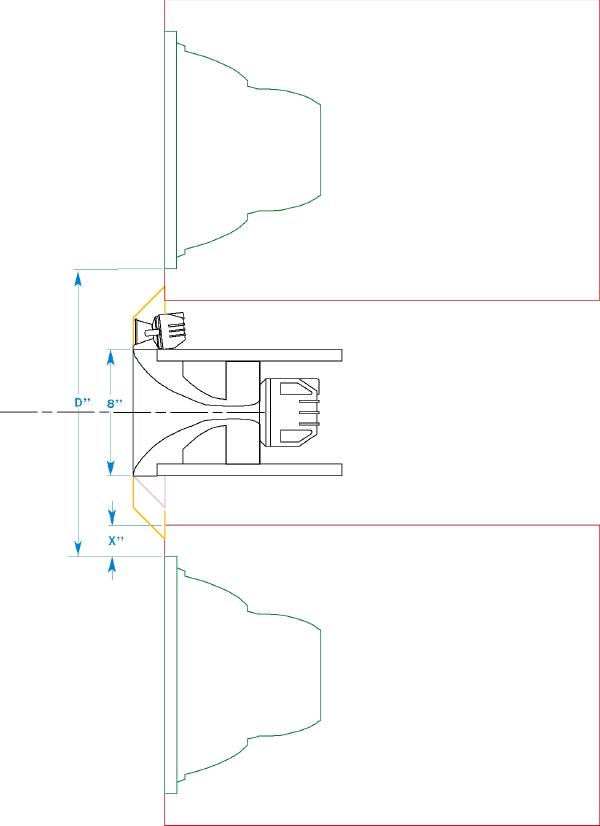

I have started working on the Sonoglass

composite HF-UHF horn. I have a few questions for Tim and the crew.

From Tim, the mdf prototype box exterior dimensions are H 19" x W 21" x

D 27.5"

Based on that, if the woofer is centered top to bottom there is just

under 2" for the distance labeled

X.

Tim, is this correct? I

would also like to know what the distance

D

has been in your

tests. Additionally I need to know what the distance has been between

the top surface of the lower woofer cabinet and the bottom of the top

one. In this drawing there is 14". For the final design we can bring

them in closer, but only if there is a cavity in the top box to

accommodate the 045Be. A distance greater than 14" will make the

prototype easier to deal with, but I assume we would like

D

to be

as small as possible.

I am placing the two woofer boxes symmetrically about the centerline of

the mid horn. Does anyone have objection with that? It could also be

centered about a mid point between the H9800 and the 045Be.

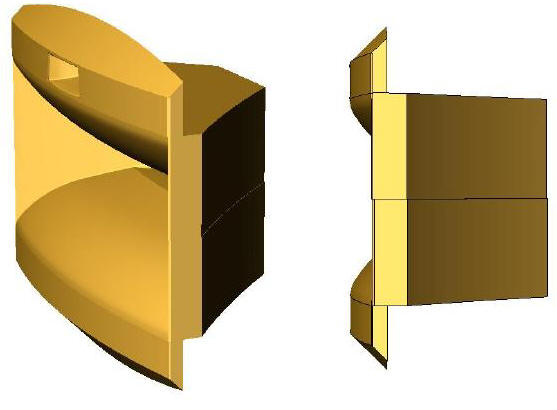

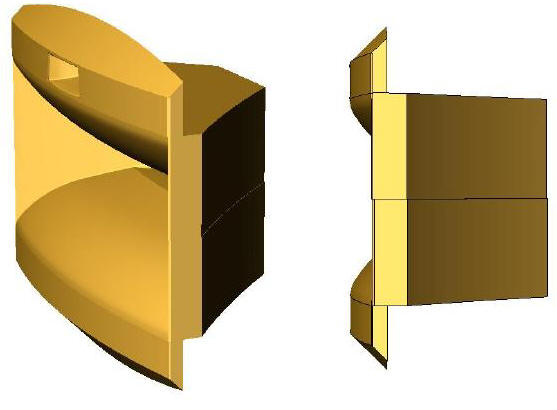

Here are a couple of rendered sketches to

help people picture what the horn will look like. I have used the MDF

horn drawing instead of an accurate Sonoglass H9800 as I don't have one

drawn up and it would be a bit of work. I think you can get an idea about what I am

proposing though.

|

|

|

|

September 4

-

Mr. Widget

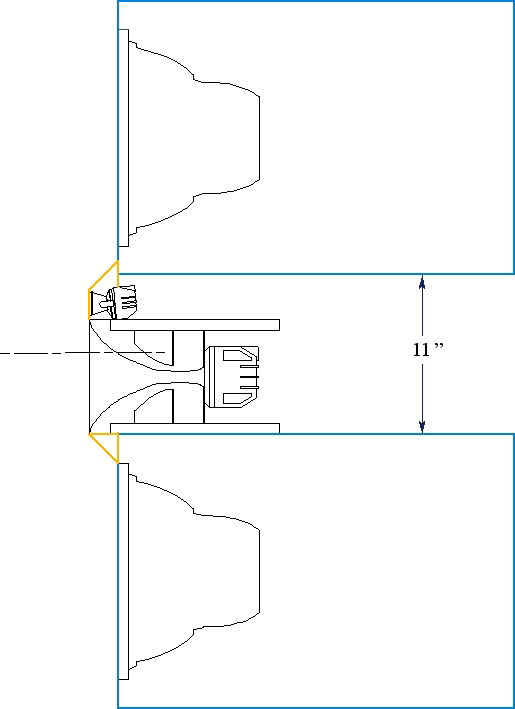

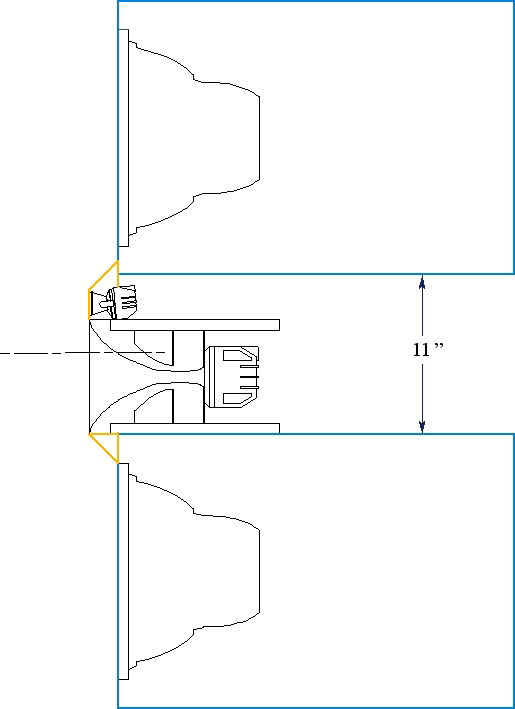

Here's another option. This drawing shows an

asymmetrical baffle treatment and puts the woofer center line as shown

by the dashed line, but it does put the woofers closer together at 30"

center to center. As the drawing shows the woofer cabinets are 11"

apart. It would be possible to make the baffle lip symmetrical but that

would separate the woofers by two more inches.

|

|

|

|

September 7 -

TimG

I would vote for making the horn assembly

symmetrical so the midrange driver is centered in the MTM. If we need

the woofers closer together I could eventually build some new baffles

for the prototype boxes that allow the drivers to go to the edge of the

box. It's not really an MTM if the tweeter isn't in the middle (ignoring

the 045 for convenience).

|

|

|

|

September 7

-

Mr. Widget

Moving the woofer to the edge won't change

much as the chamfered area above the horn uses up most of the space.

I will make the composite horn rig symmetrical and build it as tight as

possible. It will probably yield a test set up where the woofers are

just under 32" center to center.

|

|

|

|

September 7

-

Giskard

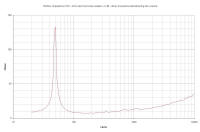

I just received the low pass and high pass

filter components today and could begin building either in the next few

days. I have yet to order the bandpass. Just for fun - here's the 1500AL

mounted in a 4.00 cubic foot sealed test cube. One should note the

standing wave at ~ 350 Hz.

The standing wave can be

seen in the impedance curve. It is the blip at ~ 350 Hz. With the

oscillator set at that frequency the most horrid sound emanates from the

system as would be expected. The internal dimensions of the enclosure

are 484 mm cubed.

|

|

|

|

September 11

-

Giskard

The addition of 2" thick OC fiberglass on

all panels is sufficient to reduce the standing wave ~ 350 Hz. Impedance

drops to "normal" and the objectionable sound is greatly attenuated.

This doesn't necessarily have anything to do with the project. I just

thought it might be interesting to some that the standing waves

generated in a cube are definitely objectionable and are viewable in an

impedance run.

Some closed box data:

driver mounted normal

4.0 cu ft gross

no fill

Qtc = 0.56

Fc = 49.8

driver mounted normal

4.0 cu ft gross

2" OC fiberglass on all panels except baffle

Qtc = 0.54

Fc = 47.8

|

|

|

|

September 12

-

Giskard

I ran the TS parameters using BB6P just for

fun and here is what I got.

One can recreate the whole thing by using the \Test\Driver feature and

entering the following:

Manufacturer: JBL

Model Name: 1500AL

Serial Number: 1500AL-01686

Resistor: 982 ohms

Piston Diameter: 13.18 in

Voice Coil Resistance (Re): 5.4 ohms

Voltage (V1): 10.04 volts

Frequency (Fs): 27.9 Hz

Voltage (V2): 1.514 volts

Frequency (F1): 21.4 Hz (.289 volts)

Frequency (F2): 39.5 Hz (.289 volts)

Volume (Vb): 4.195 cu ft (includes inverted cone volume and enclosure

cutout volume)

Frequency (Fc): 48.0 Hz

Voltage (V2): 1.47 volts

Frequency (F1): 40.7 Hz (.285 volts)

Frequency (F2): 58.3 Hz (.285 volts)

results

Mechanical Parameters

Fs = 27.9 Hz

Fc = 48 Hz

Qms = 8.072

Qmc = 14.07

Vas = 248.6 liters

Cms = 0.226 mm/N

Mms = 0.144 kg

Rms = 3.128 mohms

P-Dia = 13.18 in

Sd = 880.2 sq.cm

Electrical Parameters

Qes = 0.305

Qec = 0.549

Re = 5.4 ohms

BL = 21.13 N/A

Electromechanical Parameters

Qts = 0.294

Qtc = 0.529

no = 1.704%

1-W SPL = 94.46 dB

|

|

|

|

September 13

-

Giskard

They "look good" in 4.0 to 5.0 cubic foot

volumes tuned to ~ 28 Hz.

This volume/tuning should respond very well to room placement and/or EQ.

Just a few dB at 28 Hz should do wonders in the right room.

It is easy to see why Tim thinks sealed sounds decent too. I would

imagine room gain would fill in the bottom nicely. Again, a few dB of

VLF/LF EQ with the sealed system could be very interesting. Excellent

transient character!

I have yet to determine the port length for the prototype boxes for this

tuning. I did unpack one this weekend to look at it. It sure isn't as

thick as a cardboard mail tube or PVC pipe. I'm holding off cutting the

requisite holes in the box until I do a few more 15" driver measurements

(1500SUB, 2234H, and 2235H).

I also worked on the low pass filter mounting boards. I hope to have the

low pass filters built and shipped to you by the weekend. No switches,

you will need to change the damping by hand. I'll include the extra

resistors which easily screw into the terminal strips. I'll have the

default damping already installed. I'd like you to do sealed box

measurements with the filters first before venting the enclosures. All

the components on the boards attach via terminal strips and tie wraps so

all the components are easily removed and replaced. Very "prototypical"

as opposed to PC board mounted and such.

|

|

|

|

September 22 -

Giskard

I

have received all the inductors, capacitors,

and resistors for the prototype networks as of last night.

Big, heavy, expensive, TOTL stuff...

I'm going to go looking for nylon bolts and brackets today.

|

|

|

|

September 29 -

Giskard

Here are the finished low pass network

prototypes. With a 3.9 ohm dummy load minimum impedance is 3.8 ohms. The

large "cheap" capacitors are bypassed with polypropylene & foil and

polystyrene & foil capacitors. These bypass capacitors are easily

unhooked for listening tests, with and without, to hear the effects with

the dual 1500AL transducers. The Mills resistors are set for maximum

damping for flattest LF response

|

|

|